Description

Equipment Description

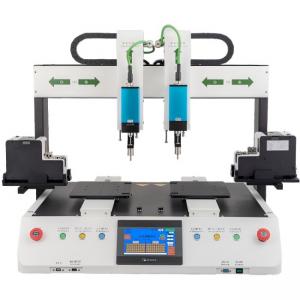

Desktop automatic soldering machines have a wide range of applications including electronic components, circuit boards, etc. They adopt advanced motion - control and intelligent soldering techniques. They are compact in structure and convenient to operate, improve the quality and efficiency of soldering, and reduce costs. They are highly - efficient and reliable soldering equipment.

Specifications

|

Model |

TBT331S-1R |

TBT441S-1R |

|

Maching Size |

L673*W613*H865mm |

L773*W713*H865mm |

|

Working Range |

X:300mm, Y:300mm, Z:100mm |

X:400mm, Y:400mm, Z:100mm |

|

Maximum Moving Speed |

X,Y 600-800mm/s,Z 400mm/s |

X,Y 600-800mm/s,Z 400mm/s |

|

Repeated accuracy |

士0.02mm |

士0.02mm |

|

Working Valtage |

AC220V/110V 50-60Hz |

AC220V/110V 50-60Hz |

|

Working Air Pressure |

0.4 to 0.8 Mpa |

0.4 to 0.8 Mpa |

|

Drive Method |

Motor + synchronous belt + linear guide |

Motor + synchronous belt + linear guide |

|

Files Storage |

Around 1000 files |

Around 1000 files |

|

Programming Mode |

Teach Pendant |

Teach Pendant |

|

Temperature control range |

0-550C° |

0-550C° |

|

Working environment |

-5~40℃,humidity 20%~95% |

-5~40℃,humidity 20%~95% |

Soldering Mechanism

Run Mode: Through the application of a multi-axis drive manipulator and software control, the soldering head can achieve precise positioning. This enables accurate movement to the designated welding points, ensuring high-precision operation.

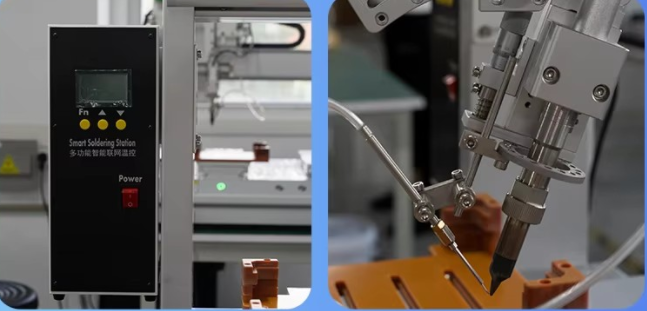

Soldering Manner: Utilize thermostatic heating of the soldering iron under high-frequency eddy current. This heating method provides stable and efficient heat transfer, ensuring the solder reaches the appropriate melting temperature quickly and evenly for better soldering quality.

Working Principle: Fix the soldering iron on the manipulator. When in operation, the manipulator moves the soldering iron to the appointed soldering coordinates. At the head of the soldering iron, solder wire is fed automatically. Under high temperature, the solder wire melts and fuses with the target, forming a reliable joint. This process is automated and repeatable, guaranteeing consistent soldering results and improving production efficiency.

Main application scenarios

Features

1. Versatile Product Applicability and Customizable Temperature Setting

It is applicable to a wide range of different products. The soldering temperature can be freely adjusted according to the specific requirements of each product, providing flexibility and precision in the soldering process. This allows for optimal soldering conditions for various materials and components, ensuring strong and reliable solders.

2. User-Friendly Handheld LCD Teaching Pendant for Easy Programming

Equipped with a handheld LCD Teaching Pendant, the programming process is straightforward and simple to learn. Operators can quickly and conveniently input and modify soldering programs, reducing the learning curve and increasing operational efficiency. This intuitive interface makes it easy for both new and experienced users to set up and adjust soldering operations.

3. Rapid Heat Recovery and Long-Lasting Solder Tip

During the soldering process, the solder tip features rapid heat recovery, enabling it to quickly return to the optimal working temperature after each soldering operation. This not only improves work efficiency but also prolongs the life span of the solder tip. A durable solder tip reduces the frequency of replacements, saving costs and minimizing downtime.

4. Dual Options for Soldering Tin Feeding Devices

There are two options available for the soldering tin feeding devices: with or without a tin breaking function. This flexibility allows users to choose the most suitable tin feeding method based on the specific soldering task and requirements. Whether it's for continuous soldering or more precise, intermittent soldering, these options can meet different production needs.

5. High-Precision Welding Positioning with ±0.02mm Accuracy

An accuracy of ±0.02mm is ensured for the welding position during production. This high level of precision guarantees that each solder joint is placed exactly where it is needed, minimizing errors and improving the overall quality and reliability of the soldered products. It is crucial for applications where accurate connections are essential, such as in the electronics industry.

6. Multiple Functional Modes and Independent Parameter Settings

It offers functions such as spot welding, drag soldering, and automatic cleaning. Each solder joint has independent parameters for preheating, the length of the welding wire, preheating time, welding time, solder wire return time, lifting height, etc. This allows for fine-tuning of the soldering process for different types of joints and materials, ensuring consistent and high-quality soldering results. Operators can customize these parameters to achieve the best possible soldering quality for each specific application.

7. Efficient Program Editing Functions for Enhanced Productivity

With functions like program editing for soldering points, including parameter copy, position correction, position copy, array, batch editing and modification, as well as other fast editing functions, the editing efficiency can be greatly improved. These features make it easy for operators to manage and optimize soldering programs, reducing the time and effort required for program setup and adjustment. It enables quick adaptation to changes in production requirements and improves overall production flexibility.

8. Automatic Tip Cleaning by Airflow for Easy Maintenance

The automatic tip cleaning function uses airflow to clean the residual dross on the tip. This makes it easy to remove any accumulated debris, ensuring the solder tip remains clean and in good working condition. Regular and effective tip cleaning helps maintain the quality of soldering and extends the life of the tip, reducing the need for frequent manual cleaning and improving the overall stability of the soldering process.

9. Quick and Easy Solder Tip Replacement with Sleeve Design

The sleeve design allows for the soldering tip to be replaced quickly and easily. This feature simplifies maintenance and reduces downtime when the tip needs to be replaced due to wear or damage. Operators can quickly swap out the tip, minimizing interruption to the production process and ensuring continuous operation.

10. High-Power Heating Controller for Rapid Temperature Rise

The high-power heating controller ensures that the tip temperature can reach 350°C within 30 seconds. This rapid heating capability allows for quick start-up and efficient operation, reducing waiting time and increasing productivity. It is especially useful in high-volume production settings where time is of the essence.

11. Comprehensive Parameter Settings for High-Quality Soldering

All kinds of parameters can be set to ensure high welding quality. By precisely adjusting parameters such as temperature, time, and wire feed, the soldering process can be optimized for different materials and joint requirements. This comprehensive parameter setting capability allows for consistent and reliable welding results, meeting the strict quality standards of various industries.

Our Factory

Tbeite Technology Limited is a high-tech enterprise that specializes in the research and development, production, and sales of performance automatic equipment. The company is dedicated to offering customers high-quality and innovative products and services. It mainly concentrates on Automatic Screwdrivers, Automatic Screw Feeders, Automatic Fluid Dispensers, Automatic Riveters, soldering machine and some related automatic equipment.

Packing&Shipment