Description

Product Description

The automatic dispensing machine is a highly efficient and precision instrument designed for various industrial applications. It can accurately apply adhesives, sealants, and other fluids with consistent volume and speed.

Equipped with advanced technology, it offers stable and reliable performance. The machine is capable of handling different types of materials and viscosities, ensuring optimal results every time.

With its automated operation, it saves time and labor costs while improving production efficiency. It can be easily programmed to meet specific dispensing requirements, making it a versatile tool for manufacturers.

The automatic dispensing machine is built with quality materials and components, ensuring durability and long service life. It is user-friendly and easy to maintain, providing a convenient solution for industrial production.

Specification

Model

TBT331-HM

TBT441-HM

TBT551-HM

TBT661-HM

Maching Size

L624*W612*H648mm

L724*W713*H648mm

L824*W813*H648mm

L924*W913*H648mm

Working Range

X:300mm, Y:300mm, Z:100mm

X:400mm, Y:400mm, Z:100mm

X:500mm, Y:500mm, Z:100mm

X:600mm, Y:600mm, Z:100mm

Maximum Moving Speed

X,Y 600-800mm/s,Z 400mm/s

X,Y 600-800mm/s,Z 400mm/s

X,Y 600-800mm/s,Z 400mm/s

X,Y 600-800mm/s,Z 400mm/s

Repeated accuracy

士0.02mm

士0.02mm

士0.02mm

士0.02mm

Working Valtage

AC220V/110V 50-60Hz

AC220V/110V 50-60Hz

AC220V/110V 50-60Hz

AC220V/110V 50-60Hz

Working Air Pressure

0.4 to 0.8 Mpa

0.4 to 0.8 Mpa

0.4 to 0.8 Mpa

0.4 to 0.8 Mpa

Drive Method

Motor + synchronous belt + linear guide

Motor + synchronous belt + linear guide

Motor + synchronous belt + linear guide

Motor + synchronous belt + linear guide

Files Storage

Around 1000 files

Around 1000 files

Around 1000 files

Around 1000 files

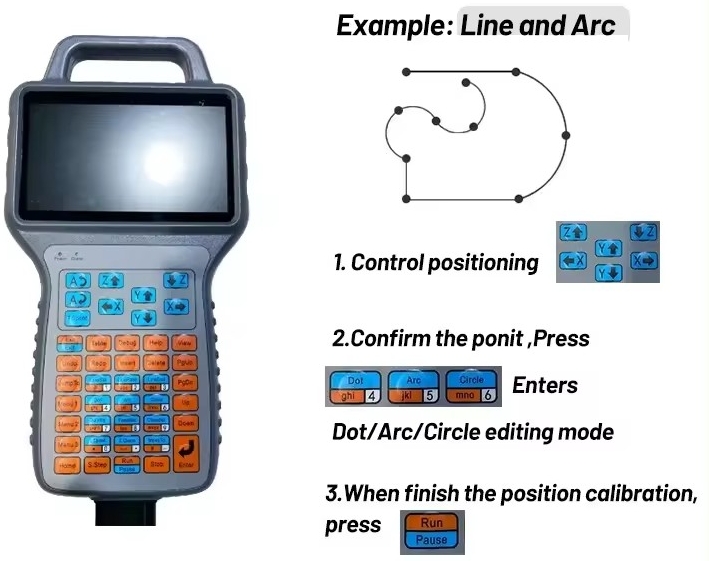

Programming Mode

Teach Pendant

Teach Pendant

Teach Pendant

Teach Pendant

Dispensing Path

Dot/Line/Arc/Circle

Dot/Line/Arc/Circle

Dot/Line/Arc/Circle

Dot/Line/Arc/Circle

Working environment

-5~40℃,humidity 20%~95%

-5~40℃,humidity 20%~95%

-5~40℃,humidity 20%~95%

-5~40℃,humidity 20%~95%

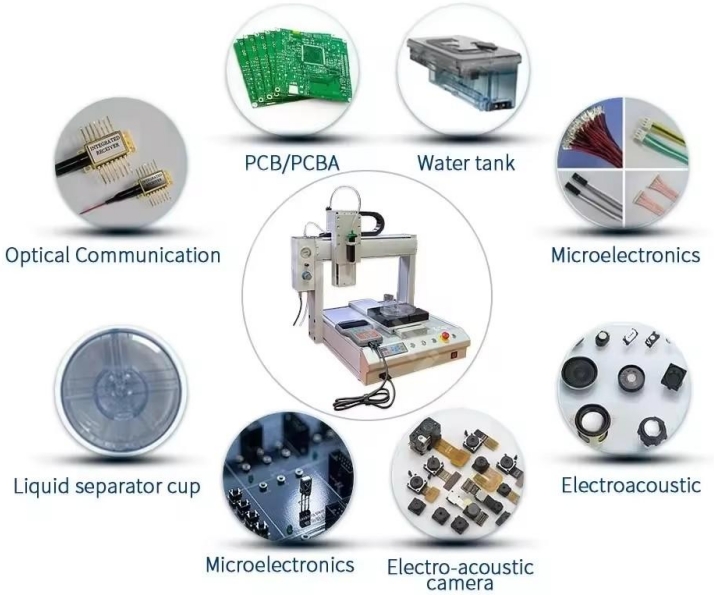

Applied Fluid and Industry

Programming Path

Product Features

1. English Panel, Easy to Operate: The English control panel is designed for user-friendly operation, ensuring that users can easily navigate and control the device.

2. Glue Dispenser Function: Capable of Drawing Various Shapes. It can draw points, lines, surfaces, arcs, circles, and irregular curve continuous complements, as well as achieve three-axis linkage. This versatility allows for precise and flexible glue dispensing, meeting different application requirements.

3. Adjustable Glue Parameters: You can set the glue size, glue speed, dispensing time, and stopping glue time. It ensures stable glue exudation without any glue leaking or dripping, providing a reliable and consistent dispensing process.

4. High-Quality Glue Dispensing via Parameter Adjustment of Screw: By adjusting the parameters of the screw, it is possible to satisfy high-quality glue dispensing, ensuring the accuracy and quality of the dispensing operation.

5. Precise Stepper Motor with Numerical Control: Equipped with a precise stepper motor that enables numerical control, offering accurate positioning and control during the dispensing process.

6. Customizable Work Platform: According to the production process, the work platform can be installed with positioning PIN, glue guns, and baseboard heating temperature controlling device, allowing for customization to meet specific production needs and improving the overall efficiency and quality of the production process.

Delivery, shipping and service

After-sales service is only the beginning of our eternal partnership. We are available 24 hours a day, seven days a week, and act as a guardian star, guiding you through your usage experience.

All machines are safely packed in plywooden cases; robust packing ensures that the machine is not damaged during transit.