Description

Equipment Introduction

A key equipment in modern manufacturing. Controlled by computer, it precisely manages the screw fastening process with accurate parameter setting. Has an efficient feeding system and intelligent screwdriver, handles different screw types, and features a user-friendly interface for easy operation and monitoring. It boosts efficiency, quality, and reduces costs and errors, crucial for various industries to ensure product integrity.

Specifications

|

Models |

TBT5441-SXV |

|

Size: LxWxH |

750×780×950mm |

|

Movement Range: X*Y*Z |

500*400*100mm |

|

Fastening Range: X*Y*Z |

180*400*100 mm |

|

Weight |

150 kg |

|

Drive mode |

Closed-loop stepper or servo |

|

Transmission mode |

Screw rod or synchronous belt |

|

Control system |

Industrial computer with motion control card |

|

CCD Camera |

Automatic camera calibration |

|

Screw feeding mode |

Air Suction / Magnet Suction/Air Shooting |

|

Screwdriver |

Servo Screwdriver |

|

Positioning accuracy |

±0.02 |

|

Fastening time |

1.5 - 1.8s / screw |

|

Program stores |

999 Groups, 100 Points / Program |

|

Display method |

Touch Screen |

|

Supply voltage |

Single-phase 220V / 110V |

|

Power |

1350W |

|

Air supply (Mpa) |

0.5-0.7 Mpa |

|

Screwdriver Qty (Set) |

1 |

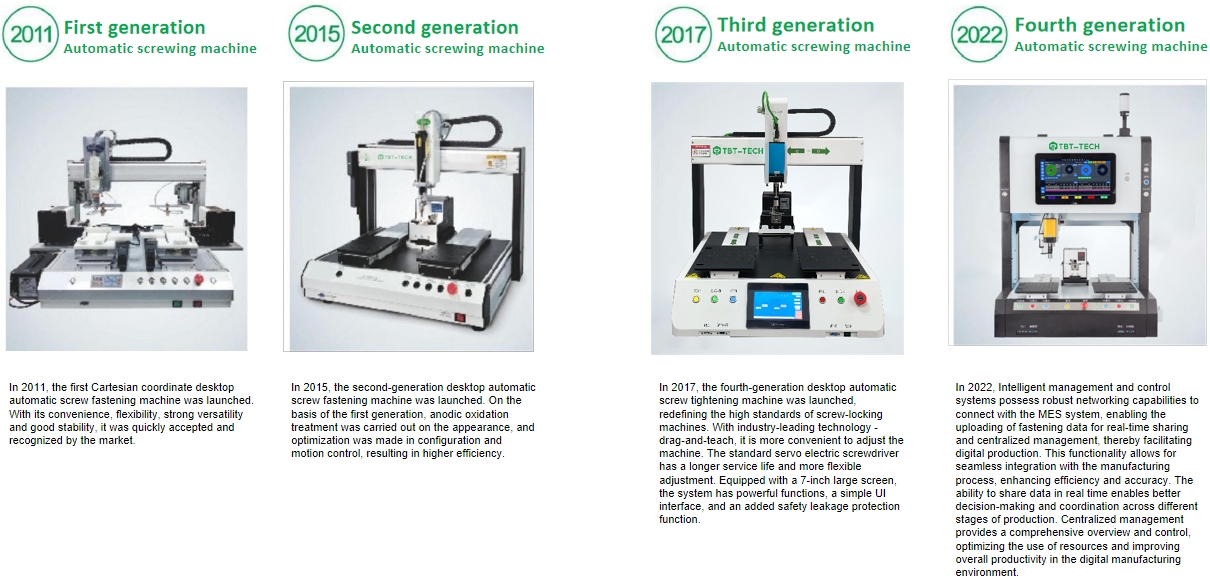

Development history of automatic screwing machines

On the road of development, we have been working hard all the time,

constantly improving our products and providing customers with high-quality products and good after-sales service

Product Functions and Highlights Analysis

1: The screw feeding method can support vacuum suction/magnetic suction (the suction nozzle needs to be replaced for switching). It can fasten stainless steel screws and spurved surfaces, and surfaces with different heights (by magnetic suction);

2: The rotation speed and torque of the intelligent screwdriver can be set on the industrial control computer with high precision (error±5%), low noise, long service life, and maintenance-free;

3: The machine adopts solid aluminum machining and sheet metal shell, with strong rigidity and high stability. The height position of the feeder and the Z-axis structure can be adjusted freely, supporting products with different heights and having strong compatibility. It is equipped with a pair of safety gratings, which is beautiful and safe.

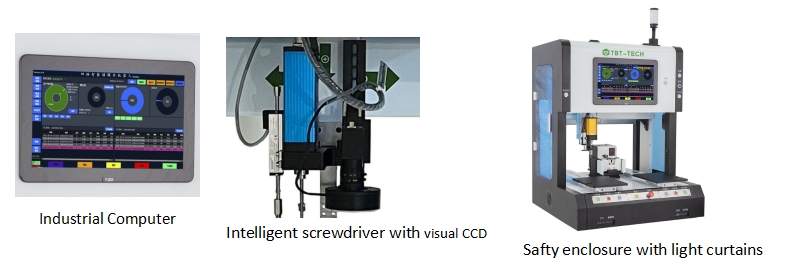

4: It comes with an industrial control PC computer (supporting wired Ethernet/wireless Wi-Fi).

5: It supports the collection of fastening data and can be uploaded with MES for convenient later tracing (not automatically uploaded by default, and automatic upload can be selected as an option).

6: It supports code scanning for fastening(USB code scanning gun scans barcodes/ QR codes), and the fastening screw data is automatically bound to the product barcode.

7: It supports displacement sensors (detecting floating height and automatically reversing and repairing).

8: It supports vacuum negative pressure gauges (detecting whether the screw in the suction nozzle has fallen).

9: It supports remote machine adjustment on PC and mobile terminals (an App needs to be downloaded).

10: The intelligent electric screwdriver can view the torque waveform diagram in real time.

11: It supports the later installation of visual CCD for auxiliary correction to make the screw fastening more accurate.

Exceptional Features of Intelligent Screw Fastening Equipment

I. Leading Intelligent Technology

1. Industrial Computer Mastery: Utilizes advanced control tech for precise op & intelligent management. Has strong networking to connect to MES system, uploading fastening data for real-time sharing & centralized management, aiding digital production.

2. Intelligent Parameter Setting & Monitoring: Via computer, set fastening data flexibly. View torque waveform in real-time to detect issues promptly, ensuring fastening quality stability.

II. Ensured Operational Safety

Comprehensive Safety Protection Design: Equipped with safety enclosure for physical isolation and safety light curtain for intelligent monitoring. Stops running when a person enters danger zone to guarantee operator safety.

III. Enhanced Precision for Quality Improvement

Visual CCD Assisted Precise Correction: Visual CCD system improves screw fastening accuracy. Identifies and adjusts screw position via high-precision tech, ensuring product quality.

IV. Convenient Operation to Reduce Labor Intensity

Efficient Single-worker & Single-equipment Operation: Easy to operate, requiring one worker for loading/unloading. Equipment automates screw fastening, increasing efficiency and reducing error rate.

V. Reliable Operation for Production Continuity

Automatic Alarm System & Long-term Stable Work: Has an automatic alarm system to monitor equipment status. Alerts for faults, and can work continuously over 20 hours, ensuring production tasks completion.

VI. Elevating Enterprise Image and Customization Service

1. Shaping a High-tech Production Image: Adds vitality to the production line with advanced tech and modern design, enhancing enterprise's competitiveness and brand image.

2. Personalized Customization to Meet Diverse Needs: Can be customized according to product assembly requirements, providing the best fastening solution and adapting to market changes.

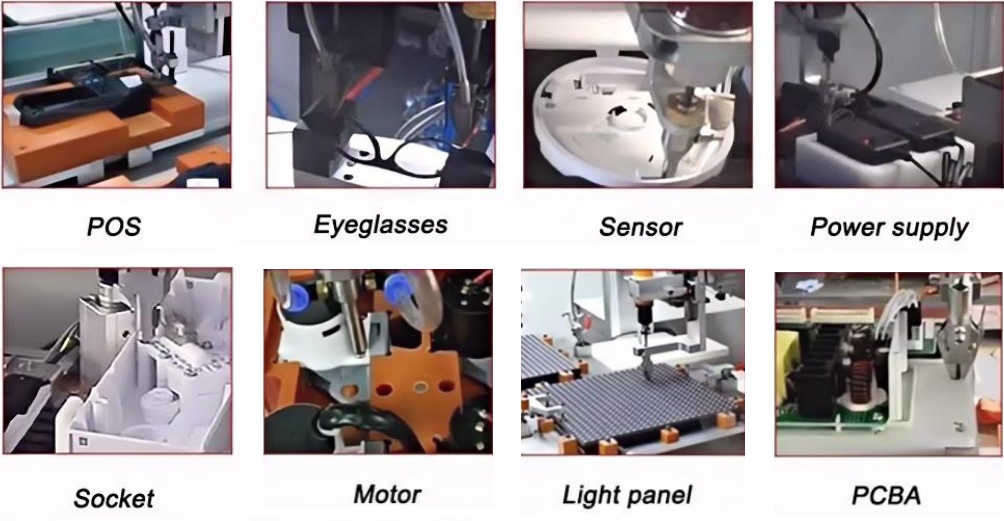

Application Cases

Automatic screw locking machines are widely used for Electronics, Home applications, LED bulbs, Auto parts, PCB assembly, Hardware, Computer board, toys, Furniture, etc...

Honor Certificates

Our Screwdriver Machine, Soldering Machine and Glue Dispensing Machine have successfully obtained the NB-CE certification issued by an authoritative EU institution. This certification holds great value, and its review process is extremely rigorous, covering in-depth evaluations of multiple dimensions such as product safety standards, environmental protection requirements, and quality control systems. Obtaining this certification fully demonstrates that our products have met the stringent standards set by the European Union in all performance indicators, and they are qualified to be sold smoothly in the EU market and even globally. It powerfully showcases our outstanding capabilities in product research and development, production processes, and quality control.

Why us

We are committed to providing customers with comprehensive solutions for automatic screwdrivers, automatic screw feeders, fluid dispensers, automatic riveters and other related automatic equipment. Mass production of our machines offers advantages in price and fast delivery. Before shipping, the machines are fully tested and carefully packaged to ensure the quality and stability of the delivered products.

Delivery, shipping and service

After - sales service is not the end, but the starting point of our eternal companionship. We are online 24 hours a day, on standby at all times, just like a guardian star, escorting you throughout your usage journey.

All the machines are with safety packing by plywooden case, solid packing ensures that the machine will not be damaged in transit.