Description

Back to Back Automatic Screwdriver Machine

Equipment Features

1. The dual-heads and dual-feeders can be secured with two separate goods and screws, which increases the tightening process's adaptability and flexibility.

2: By operating at a dual-heads dual-rails concurrently, the dual-heads screwing machine doubles efficiency and is 1.5 times more productive than the four-axis screwing machine, greatly increasing manufacturing output.

3. The screw feeding mode offers a greater variety of alternatives to accommodate various application circumstances and material properties by supporting both vacuum suction and magnetic suction modes.

4. The intelligent screwdriver ensures accurate and tailored tightening operations for a variety of objects by enabling the torque, speed, angle, and other fastening characteristics to be arbitrarily modified according to the product.

5. The HMI gives operators instantaneous, clear information and improved control capabilities by displaying the fastening condition in real time and allowing the four torsion forces to be swapped arbitrarily to satisfy greater screw fastening requirements.

6. It has a self-designed motion control card with fool programming and drag adjustment that makes programming simple and accessible, even for non-technical people. This enhances overall efficiency and user experience by streamlining the setup and operation procedure.

Equipment Introduction

The back-to-back dual-head auto screw machine is a high-efficiency industrial tool for fast and precise screw fastening. With two independent screw-driving heads in a back-to-back design, it works on two workpieces or different positions simultaneously, boosting production throughput. Equipped with torque control systems, it tightens each screw to pre-set values, preventing over/under-tightening issues like part damage or loose connections.

Highly adaptable, it adjusts to different screw sizes and types. The continuous feeding system reduces downtime, while integration with conveyor belts enables seamless production. Built with a sturdy frame, it withstands industrial use and maintains accuracy. User-friendly controls let operators quickly set parameters. Ideal for high-volume, high-quality screw fastening, it’s a vital asset for precision manufacturing.

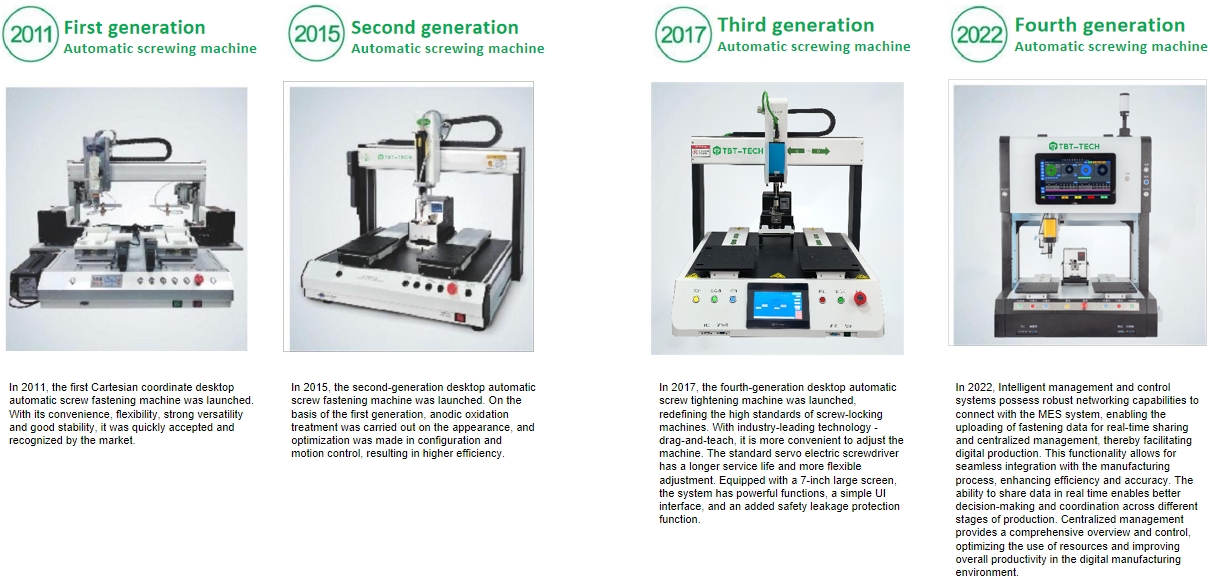

Development history of automatic screwing machines

On the road of development, we have been working hard all the time,

constantly improving our products and providing customers with high-quality products and good after-sales service.

Specifications

Models

TBT561-SX2

Size: LxWxH

930×760×740mm

Movement Range: X*Y*Z

500*600*100mm

Fastening Range: X*Y*Z

180*180*100mm

Weight

120kg

Drive mode

Closed-loop stepper or servo

Transmission mode

Screw rod or synchronous belt

Control system

PLC / Motion control card

Screw feeding mode

Air Suction / Magnet Suction/Air Shooting

Screwdriver

Servo Screwdriver

Positioning accuracy

±0.02

Fastening time

0.8 - 1s / screw

Program stores

999 Groups, 100 Points / Program

Display method

Touch Screen

Supply voltage

Single-phase 220V / 110V

Power

1000W

Air supply (Mpa)

0.5-0.7 Mpa

Screwdriver Qty (Set)

2

Application Cases

Automatic screw locking machines are widely used for Electronics, Home applications, LED bulbs, Auto parts, PCB assembly, Hardware, Computer board, toys, Furniture, etc...

Honor Certificates

Factory strength

We are committed to providing customers with comprehensive solutions for automatic screwdrivers, automatic screw feeders, fluid dispensers, automatic riveters and other related automatic equipment. Mass production of our machines offers advantages in price and fast delivery. Before shipping, the machines are fully tested and carefully packaged to ensure the quality and stability of the delivered products.